Spartan Superway Fall 2017 - Spring 2018 | Full-Scale Solar Team Members: Matthew Dianich, Chanwoong Park, Tan Ho

Monday, October 30, 2017

Week 9: Second Presentation

Connecting method between truss and track have to be figured out.

Also, figure out how to connect truss structure with shell design on top.

Use angled bracket instead of bending metals to save materials.

Solar panel comparison was not correct: Polycrystalline falls into the category of Monocrystalline.

Thursday, October 19, 2017

Week 8

For this week, solar team successfully calculated the power that is needed for the 9 m track. Since we are going to build 9 m long horizontal track, some of the values are changed to meet the requirements, especially the elevation force.

Changes:

elev_comp = 0 #(1/n_bar)*n_t*M_v*(g*z)

aux_comp = 0 #n_t*P_aux*t_s

M = 400 #(kg) Mass of fully loaded ATN vehicle

P_aux =0 # previous 3500.0 auxiliary power, W (see Wikipedia for auto air con)

Energy required, E(t_s) = 8.70e+02 J

Average trip time, 0.5 minutes

Average power, P_avg = 32 W

>> Energy per 150 vehicles <<

Energy required, E(t_s) = 1.305e+05 J

Average trip time, 0.5 minutes

Average power, P_avg = 4.73e+03 W

KE loss = 3.71e+02 J ---> 42.6%

Air drag loss = 2.26e+01 J ---> 2.6%

Rolling resistance loss = 4.77e+02 J ---> 54.8%

Aux power loss 0.00e+00 J ---> 0.0%

Based on the power was calculated below, there are some of possible solar panels that can be used for the full scale solar design.

Changes:

elev_comp = 0 #(1/n_bar)*n_t*M_v*(g*z)

aux_comp = 0 #n_t*P_aux*t_s

M = 400 #(kg) Mass of fully loaded ATN vehicle

P_aux =0 # previous 3500.0 auxiliary power, W (see Wikipedia for auto air con)

V_l = 1.5 # line speed, m/s

V_w = 1.5 # average wind speed, m/s

Result:

** Energy per vehicle **Energy required, E(t_s) = 8.70e+02 J

Average trip time, 0.5 minutes

Average power, P_avg = 32 W

>> Energy per 150 vehicles <<

Energy required, E(t_s) = 1.305e+05 J

Average trip time, 0.5 minutes

Average power, P_avg = 4.73e+03 W

KE loss = 3.71e+02 J ---> 42.6%

Air drag loss = 2.26e+01 J ---> 2.6%

Rolling resistance loss = 4.77e+02 J ---> 54.8%

Aux power loss 0.00e+00 J ---> 0.0%

Based on the power was calculated below, there are some of possible solar panels that can be used for the full scale solar design.

Due to aesthetics we should use thin film:https://www.amazon.com/ALLPOWERS-Monocrystalline-Lightweight-Connector-Compatibility/dp/B07195WHHX/ref=sr_1_5?s=lawn-garden&ie=UTF8&qid=1508262264&sr=1-5&keywords=flexible+monocrystalline

18 panels x 169.99= 3059.82

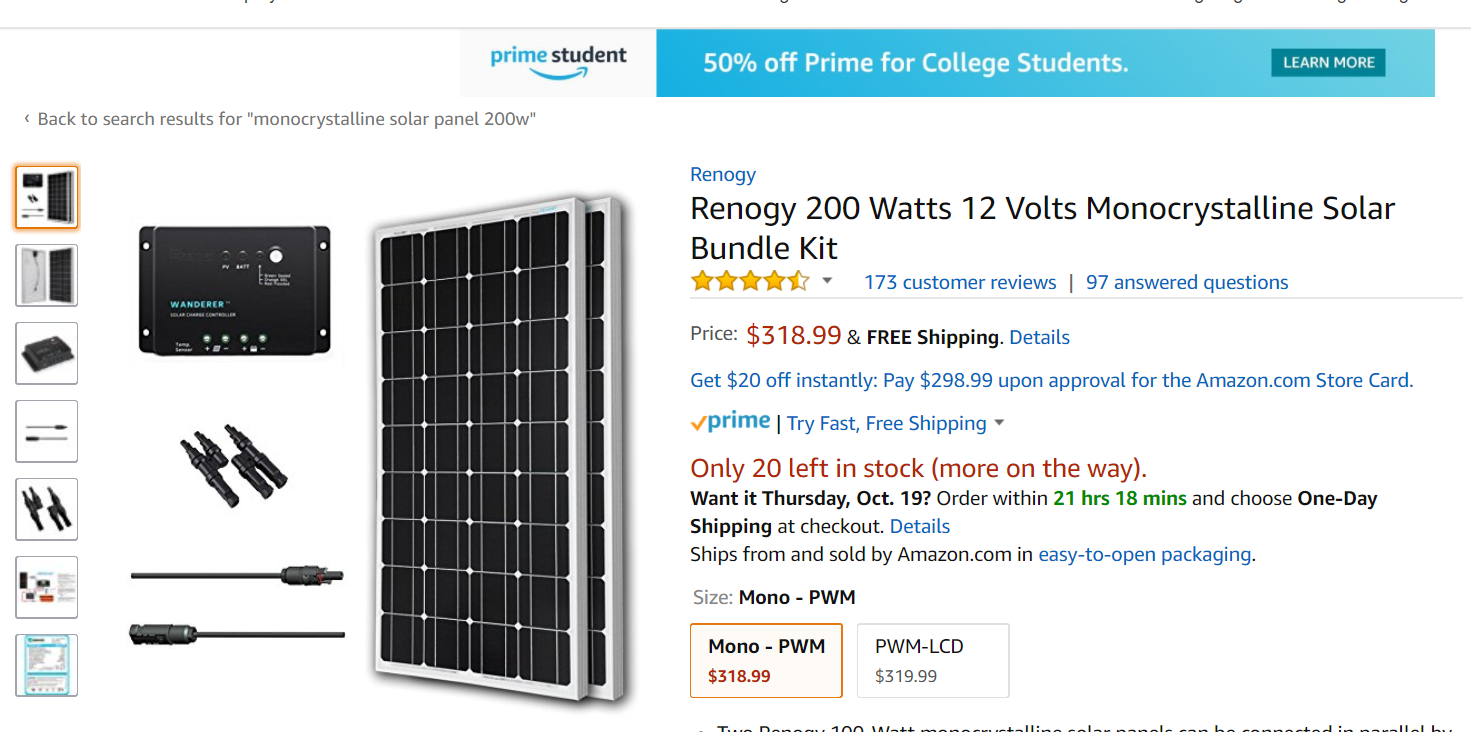

$318.99x9=$2870.91

Convertor:

Wednesday, October 4, 2017

Week 7

The time normally reserved meeting and brainstorming was spent listening to a lecture from Professor Du and taking a quiz on project report writing guidelines. The time that was left for class was spent discussing the discrepancies in the energy calculations. The team is currently attempting to reverse engineer the required power input equation of the full-scale track, which was approximately 5.61*10^6 kWh. As of right now, the team is still off by about 100,000 kWh for the power calculation, which is no small discrepancy.

More design details were discussed in a meeting with Dr. Furman, who encouraged the team to continue pushing out design ideas and sketches as rapidly as possible. Putting out a high number of sketches should be an effective method for generating ideas.

More design details were discussed in a meeting with Dr. Furman, who encouraged the team to continue pushing out design ideas and sketches as rapidly as possible. Putting out a high number of sketches should be an effective method for generating ideas.

Tuesday, October 3, 2017

Week 6: Energy Calculations | Initial Design Plan

Two documents were utilized to compute the calculation

1) 2016-06-13.BJF.EnergyCalculation.pdf

2) Case Study of a Solar Power Installation for an Automated Transit Network in San José by Leonardo C. Branco, Eric L. Rosenfeld, Durval Marques de Queiroz Neto, and Burford J. Furman

Below is the group's work/discussion for the week.

1. Performed energy calculations. Energy Calculation was computed to be 3.51E+06 kWh or J (=3510000 kWh or J) while the value on the pdf file was 3.68E+06 kWh or J (=3680000 kWh or J). We used Microsoft Excel to calculate the value. The team is unclear about what the ρ (rho) value would be in the equation. In the pdf file, rho value was given as 1.275 kg/m^3, which is the density of the air on page 5, as well as motor efficiency on page 2. Our team computed the calculation using 1.275 kg/m^3 for rho value.

2. Energy calculation result needs to be confirmed by Dr. Furman on 10/4 Wednesday so the team could start working on CAD model using Solidworks by the end of this week.

3. The team needs to figure out how to connect/attach the solar panel rack onto the guideway.

4. Ask Dr. Furman about admission ticket to TechShop San Jose to explore possible methods to connect rack onto the guideway.

1) 2016-06-13.BJF.EnergyCalculation.pdf

2) Case Study of a Solar Power Installation for an Automated Transit Network in San José by Leonardo C. Branco, Eric L. Rosenfeld, Durval Marques de Queiroz Neto, and Burford J. Furman

Below is the group's work/discussion for the week.

1. Performed energy calculations. Energy Calculation was computed to be 3.51E+06 kWh or J (=3510000 kWh or J) while the value on the pdf file was 3.68E+06 kWh or J (=3680000 kWh or J). We used Microsoft Excel to calculate the value. The team is unclear about what the ρ (rho) value would be in the equation. In the pdf file, rho value was given as 1.275 kg/m^3, which is the density of the air on page 5, as well as motor efficiency on page 2. Our team computed the calculation using 1.275 kg/m^3 for rho value.

2. Energy calculation result needs to be confirmed by Dr. Furman on 10/4 Wednesday so the team could start working on CAD model using Solidworks by the end of this week.

3. The team needs to figure out how to connect/attach the solar panel rack onto the guideway.

4. Ask Dr. Furman about admission ticket to TechShop San Jose to explore possible methods to connect rack onto the guideway.

Subscribe to:

Posts (Atom)